As a retailer or supplier, you understand this experience far too well. It’s plagued you as a customer, and it’s one of the worst things standing between you and making a sale. It can also erode the long-term trust in your brand. With a sigh of frustration, the customer has either ordered what they need online or dragged themselves to a competitor down the street.

This is a common problem in the industry better known as low or no on-shelf availability (OSA). So how do you go about fixing it?

What causes low on-shelf availability?

You may already know that on-shelf availability is the measure of a product being available for sale to a shopper product at the time and place they need it. But while on-shelf availability may seem like a straightforward process, there are usually three reasons why low OSA occurs:

- A lack of inventory at a location (it’s out of stock)

- The product is in the wrong location (POG or merchandising errors)

- An item is in stock but not on the shelf (monitoring at the display is lacking)

Thankfully, there are solutions that make it easier to catch on-shelf availability challenges before, during, and after a product has sold.

Three ways to track on-shelf availability

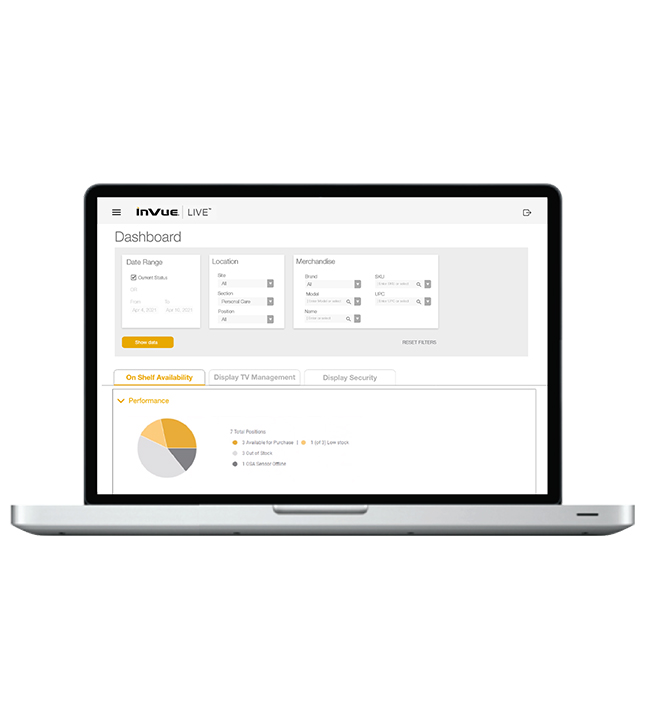

There are several products and services out there to help resolve on-shelf and product availability challenges and they typically roll up to one of three areas: retail audits (a physical store check), algorithmic software to using software to help predict out of stocks via inventory and historical sales data, or using hardware and IoT devices to check inventory data.

Depending on the number of SKUs, retail locations, and budget, one method may be a better fit than the other.

Retail audits

A common approach to prevent out of stocks and verify planogram compliance is to do a retail audit. This entails a physical visit to each location, verifying a product is in stock and displayed in the store according to the placement and pricing agreed upon.

Most retail audits are performed by a field merchandising team or third-party merchandiser on a pre-determined schedule. In this process, a team is looking at inventory levels, pricing, product condition, and if product placement is compliant with the brand’s planogram. These audits measure success in each retail environment and ensure the agreement terms are upheld between the retailer and vendor. The data is right before your eyes.

While this may be a common, desirable way of tracking product availability and planogram compliance, it’s also one of the most expensive, time-consuming, and can create a false sense of accuracy.

Site visits are limited to the manpower behind them. On average, four to six weeks can go by between each retail audit, exposing the vendor to more availability challenges without their knowledge. There’s also a significant cost behind these practices. Personnel, labor, and travel alone can add up quickly. The biggest drawback is that by the time a merchandiser has put in the time, cost, and effort to check what’s going on at the store, they are playing defense– only fixing the problem right in front of them, one at a time. Convenience matters and most customers don’t have the patience to wait that long.

Pros:

- Accuracy of data at the moment of audit

- Flexibility to make changes right away

- Consolidated truck runs – you can move product directly to the retailer with each visit

Cons:

- Expensive – personnel, labor, and travel alone will add up

- Timing – Each person may only visit a site every 4-6 weeks

- No data between visits– large gaps of time between store visits can expose a brand to more issues

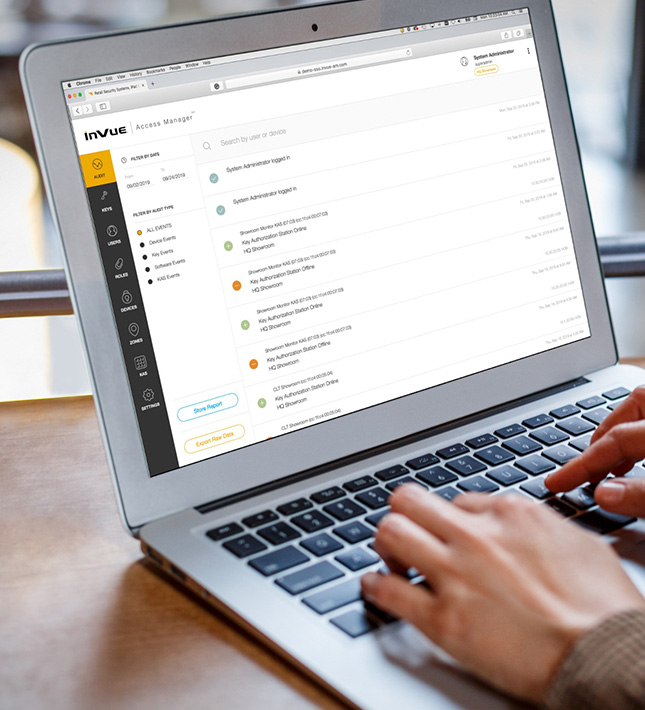

Inventory data from software

Other brands and retailers leverage algorithmic software solutions by using inventory and historical sales data. While this strategy is not as labor-intensive as a physical store visit, this practice uses data from multiple sources of the supply chain to map when sales are occurring. These solutions help answer critical questions such as: How many products arrived at the store? How many products were stocked on the shelf? How many are selling?

By resolving the questions, a store can determine when to send associates to restock shelves with merchandise from the backroom or indicate when a truck run from the merchandiser needs to be scheduled.

Pros:

- Evaluates multiple data points from sales to inventory across the supply chain

- Proactive – helps retailers get ahead of the problem

- Lighter in-store lift

Cons:

- Complexity – onboarding multiple systems and the required resources for ongoing maintenance

- Time-consuming – training and development of multiple teams to manage

- Potentially inaccurate conclusions– reports are only as good as the data going in.

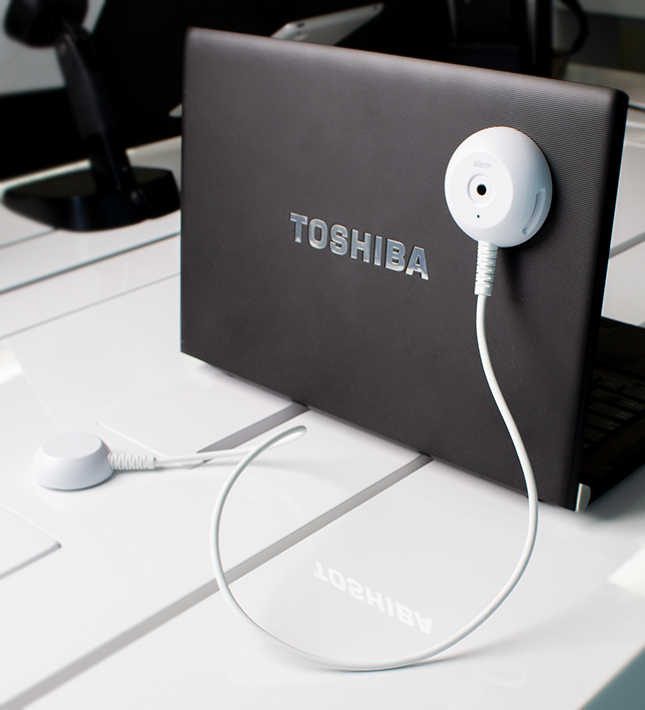

Inventory data from hardware / IoT devices

Hardware devices that physically scan or check for product movement on and off the shelf are the Goldilocks of tracking OSA. It’s not as manually intensive as a retail audit but it’s more accurate than relying solely on a software product.

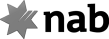

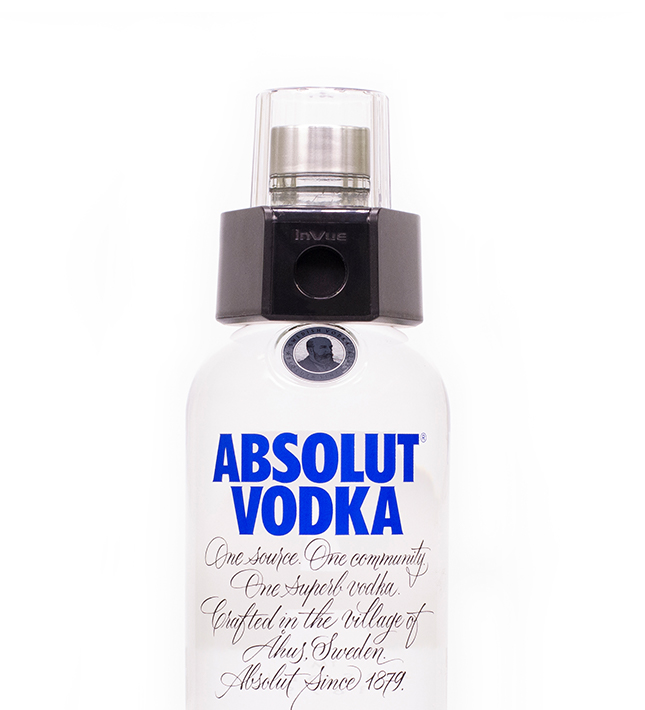

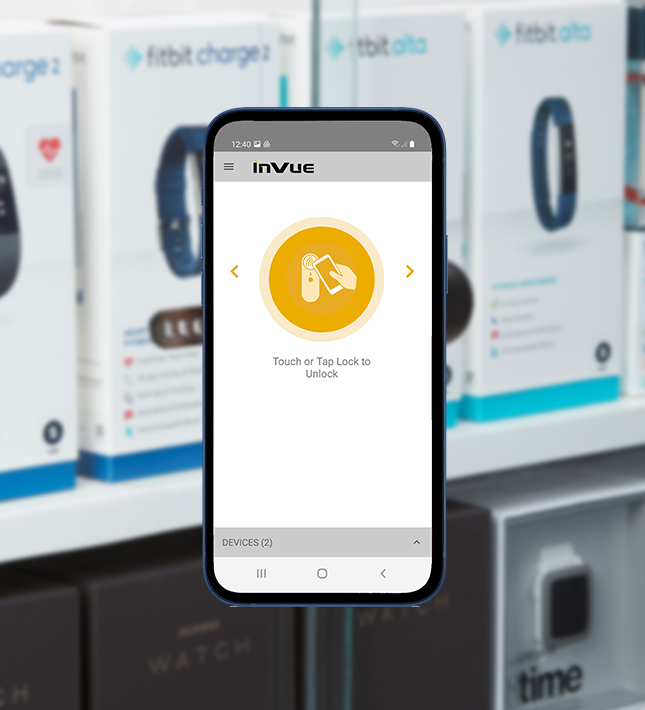

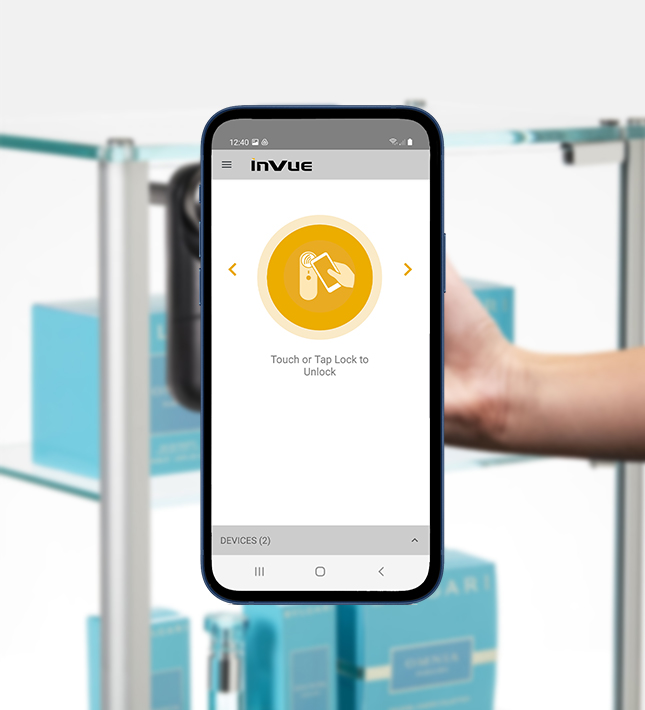

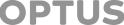

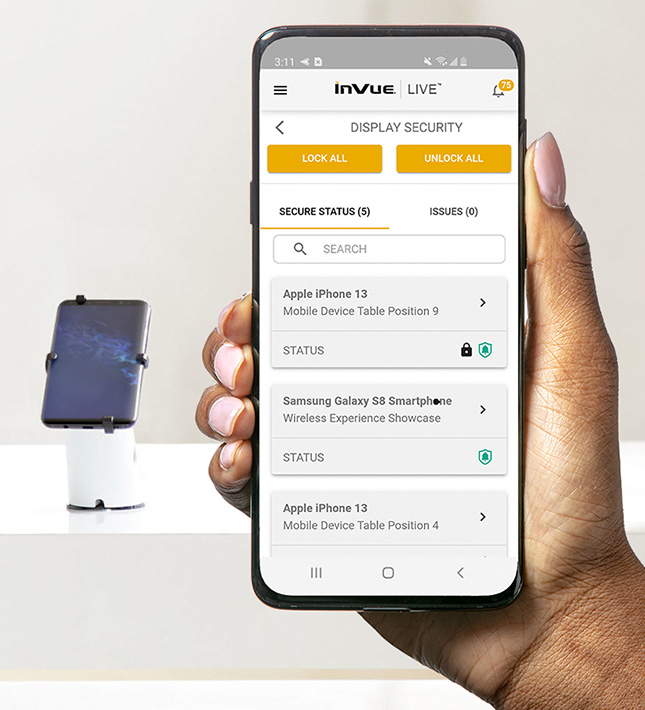

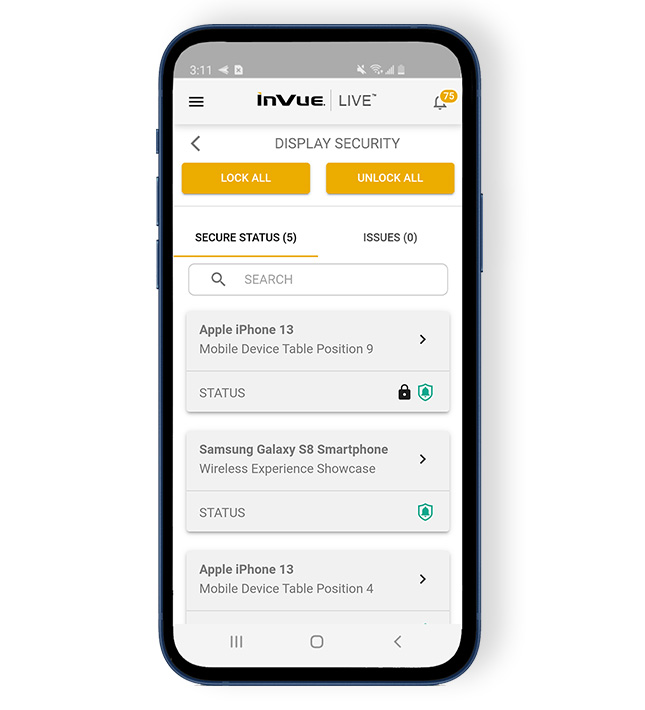

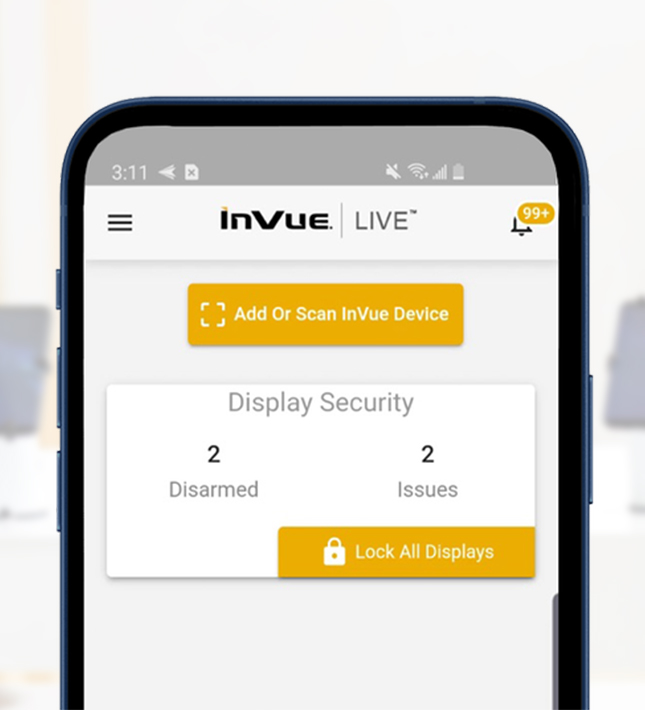

Hardware devices that track on-shelf availability range from shelf-scanning robots that will scan products on every aisle, to IoT devices that can detect the product and send real-time information directly to an associate’s mobile device. While this may seem like the perfect fit for most on-shelf availability challenges, these solutions can vary widely in their price, flexibility, set up, and ease of use and should be carefully considered individually.

Shelf-Scanning Robots

Pros:

- Accuracy – directly measures the product

- Less labor-intensive – does not require personnel

Cons:

- Expensive

- Speed – can only measure one thing at a time

- May disrupt shoppers’ experiences

IoT Devices

Pros:

- Generally more affordable

- Accuracy – directly measures the product

- Retrofittable and can be moved around the store

- Proactive – monitors and alerts of activity in real-time

Cons:

- May take more time to install

- Some solutions cannot be moved once installed

Retailers and vendors alike know just how much goes into getting products into store and ready for shoppers. If you can find the right on-shelf availability solution to track the most important part of making a sale, this could be the difference in bringing happy, loyal, repeat shoppers to your store.

Content sourced from www.invue.com