In fact in 2019, global payments provider Adyen found out of stocks ranked as the number one missed opportunity in the Australian retail sector, costing the industry an astounding $14 billion each year.

Their research indicated 83 per cent of consumers have chosen to leave a store and not make a purchase due to the item they seek being unavailable

But it’s not just the initial monetary cost of a single missed sales opportunity. Long after the customer walks away from a store dissatisfied their ongoing loyalty to both the retailer and the brand could be impacted.

What happens when an item is out of stock?

According to a recent European report by ECR Europe, customers will take one of five different courses of action if the item they seek is not available on the shelf.

- 37 per cent will buy a different brand

- 21 per cent will purchase elsewhere

- 17 per cent will return the item later

- 16 per cent buy the item in a different size

- 9 per cent do not purchase anything at all

Each of these actions ultimately impacts the customer experience, leaving the consumer dissatisfied with the retail encounter.

And that can have loyalty impacts that extend long beyond the failed purchase attempt.

As the report goes on to note, while brand substitution is high, retailers have just as much to lose as manufacturers.

Should the issue of on-shelf availability persist, after the second disappointment, the probability of a customer switching stores increases to 50 per cent, and the third disappointment sees store switching skyrocket to 70 per cent.

“Shoppers blame retailers for the deficiency and increasingly switch stores to fulfil their needs,” the report explains.

“This behaviour has a particular negative impact on retailers, since not only a single purchase, but a full shopping basket might be lost, and potentially even the customer will be gone forever.”

Lost in the last few metres

While supply issues have been well-documented in Australia in recent times, interestingly the European report found the out-of-stock problem is rarely a manufacturer one, nor is it most likely to occur between the retailer’s distribution centre and the store stockroom.

Instead, the supply challenge occurs between the retail storeroom and the shelf or display.

“The availability deteriorates along the supply chain from the manufacturer to the retailer,” the report notes.

“While the survey shows high service levels from the manufacturer’s warehouse to the retailer’s warehouse, and similarly high service levels from there to the retailer’s stockroom (98–99 per cent), this performance drops sharply over the final metres from the stockroom to the shelf (90–93 per cent).

“At the moment of truth – the moment of the intended purchase – the product is not available. Consequently, all the previous efforts made up to the stockroom will not pay off as expected.”

High inventory, poor availability

The report also goes on to note, some verticals and products are affected by out-of-stocks more than others, with a series of retail challenges all contributing to an out-of-stock event.

These include:

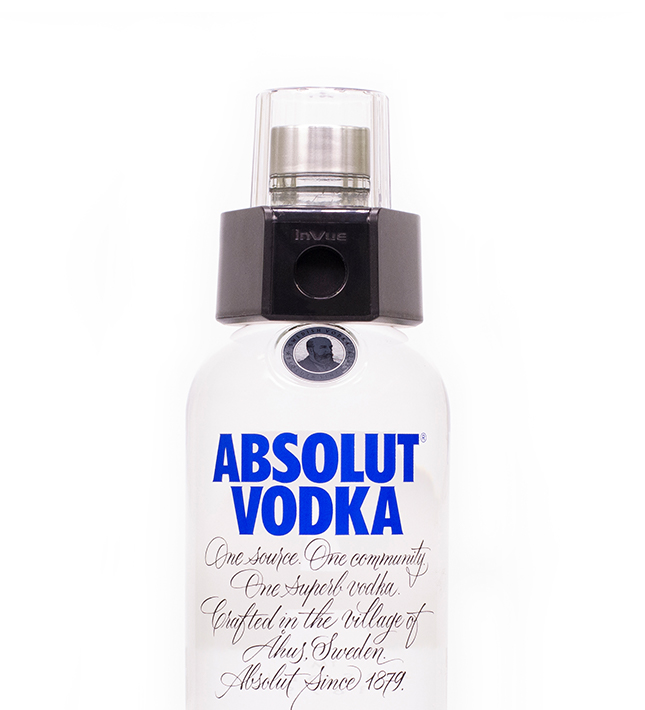

- Demanding categories – Demanding categories include products such as ice cream, spirits and ready-made meals, where demand can vary with the seasons or due to impulse purchasing and there is a trade-off between wastage and availability, along with storeroom availability.

- Non-promoted items versus promoted items – The report found promoted items have fewer out-of-stocks, but the full retail reward is lost due to non-promoted that customers might purchase as an addition being unavailable.

- Peak shopping days – Peak shopping days such as Friday and Saturday also increase the likelihood of out of stocks.

- High inventories lead to poor availability – The report also noted retailers with high inventories tended to experience more out of stocks due to the challenge of clogged stockrooms and slowed store operations.

Largely a retailer problem

Meanwhile, the report outlined 13 common reasons out-of-stocks occur and noted it’s largely a retailer problem.

The most common causes for out of stocks are:

- Delisting by store staff

- Inventory inaccuracy

- Damages & shrinkage

- Shelf replenishment

- Delivery schedule

- Operations at the distribution centre

- Supplier reliability

- Store ordering

- Distribution centre ordering

- Incorrect master data

- Forecasting inaccuracy

- Distribution centre/supplier related (other)

- Supplier related (other)

The seven layers of mitigating out of stock events

With out of stocks representing such a vast missed retail opportunity, how should retailers seek to address the issue?

According to the report, that comes down to improving retail operations across seven different layers, which can ultimately reduce out-of-stock events by up to 50 per cent.

The report authors outlined the seven layers as follows:

- Measurement

- Management attention

- Replenishment system

- Merchandising

- Inventory accuracy

- Promotion management

- Ordering system

The tools you can implement right now

So, what steps can retailers take to reduce the likelihood of out of stocks right now?

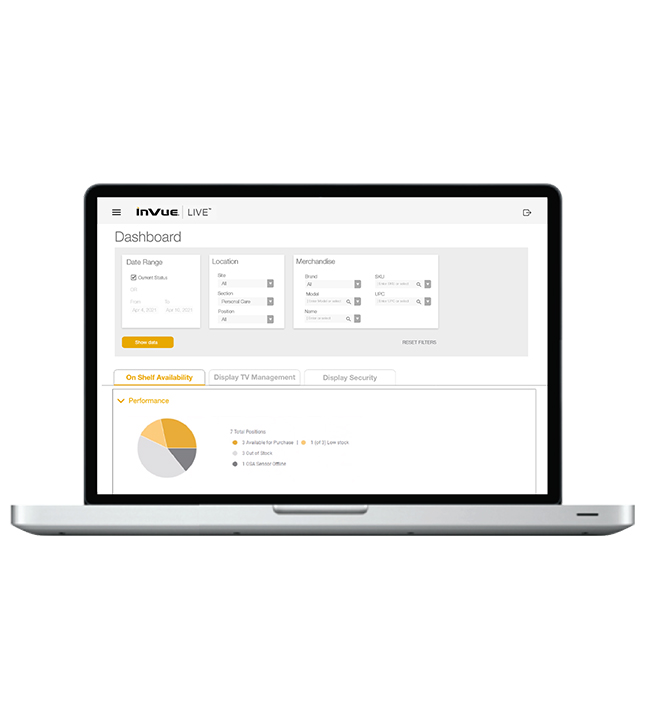

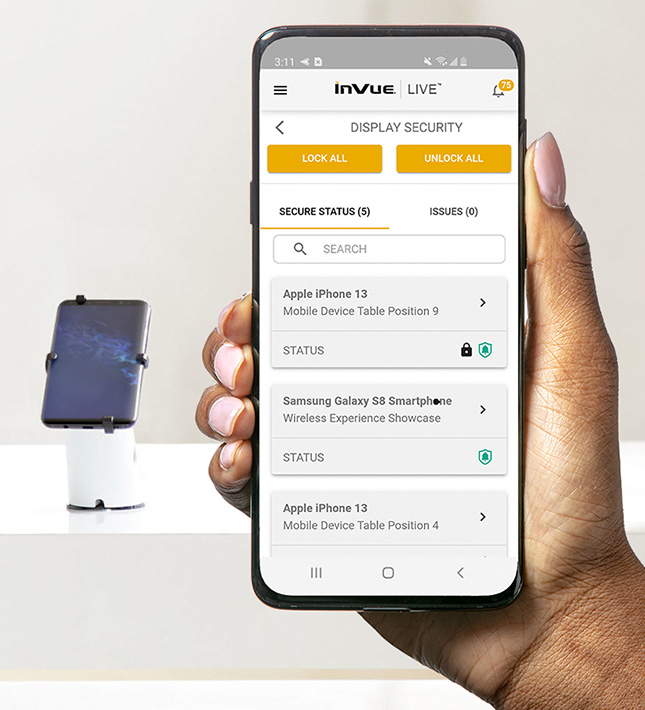

Analytics and insight – Comprehensive analytics including data from the POS, traffic counting and display interaction offers the opportunity to gain an insight into sales data, consumer purchasing behaviour and trends for improved measurement and forecasting.

RFID and inventory counting – RFID is renowned as improving inventory accuracy and the stock accuracy throughout the supply chain. Importantly it provides real-time insight into exactly what stock is available in store.

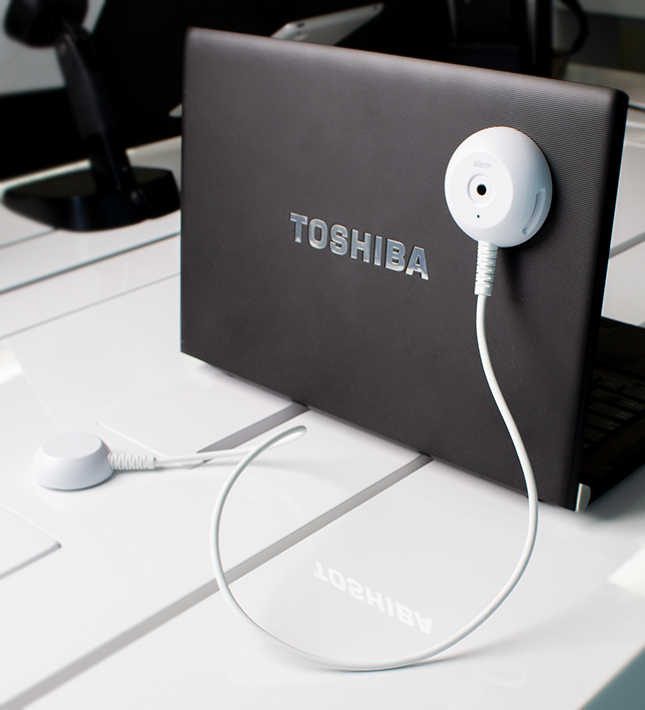

On-shelf availability sensors – With the final metres proving critical to mitigating out of stocks, on-shelf availability sensors offer a key defence that alerts staff when an item is running low and needs to be replenished.

Policies and procedures – As the report notes, a management focus on reducing out of stocks plays a major role in mitigating the issue. This then filters down through a retail organisation via the policies and procedures they implement to reduce the likelihood of a stockout occurring.

For greater insight into how to mitigate out of stocks, see here, or view our range of shelf sensors and learn how they can assist.